From its origins, the Vulcan burner sets the standards for today’s asphalt production, incorporating unique design concepts to ensure asphalt is produced at the most efficient level.

The Vulcan Burner is applicable to many industries such as Sand, Biomass, Fertilizers, Glass and Other Drying Industries.

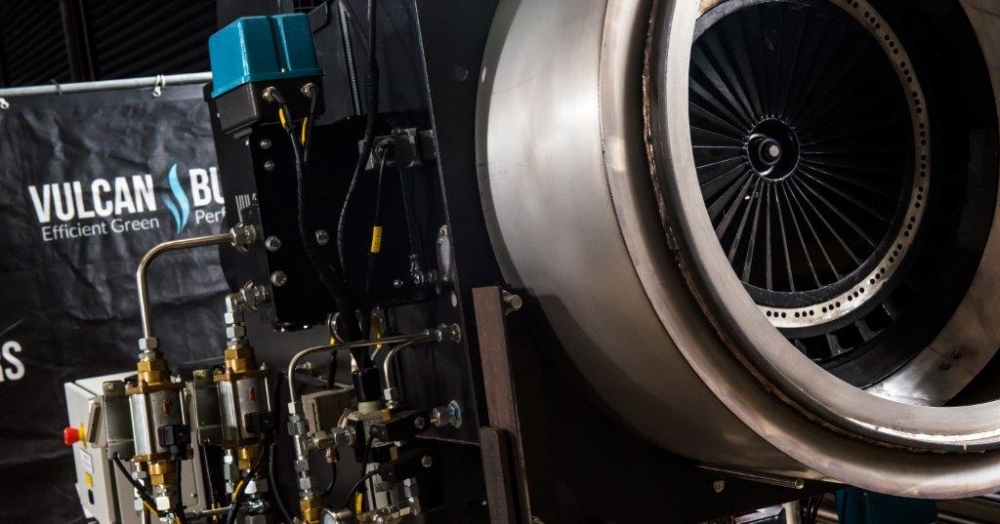

Vulcan burners have been developed with quality, efficiency and safety as key factors. The impact of our burners on the environment has also been a consideration. Since the burner range was launched in 2011, the Vulcan Burner is the number one choice in burner technology in the UK as the product has proven efficiency results with existing customers making repeat orders to improve the efficiency on their numerous sites. With the success in the UK, Vulcan Burners are now distributed throughout the world with burners in operation in North America & Asia.

In early 2024 we launched our new Vulcan Multi-fuel burner range that specialises in the use of todays fuels such as oil, natural gas and LPG but also can facilitate future fuels including rDME & hydrogen. The new Multi-Fuel range has innovated features such as instant fuel changeover, fuel mixing and has been designed to ensure low carbon and low NOx emissions.

Our wide range of Multi-fuel burners comply with the new ISO 13577-2 standards. The design and manufacturing of the Vulcan range of burners is carried out in the UK and distributed world wide.